Why Work with SPC

METAL FINISHING SOLUTIONS FOR COMPANIES IN A WIDE RANGE OF INDUSTRIES

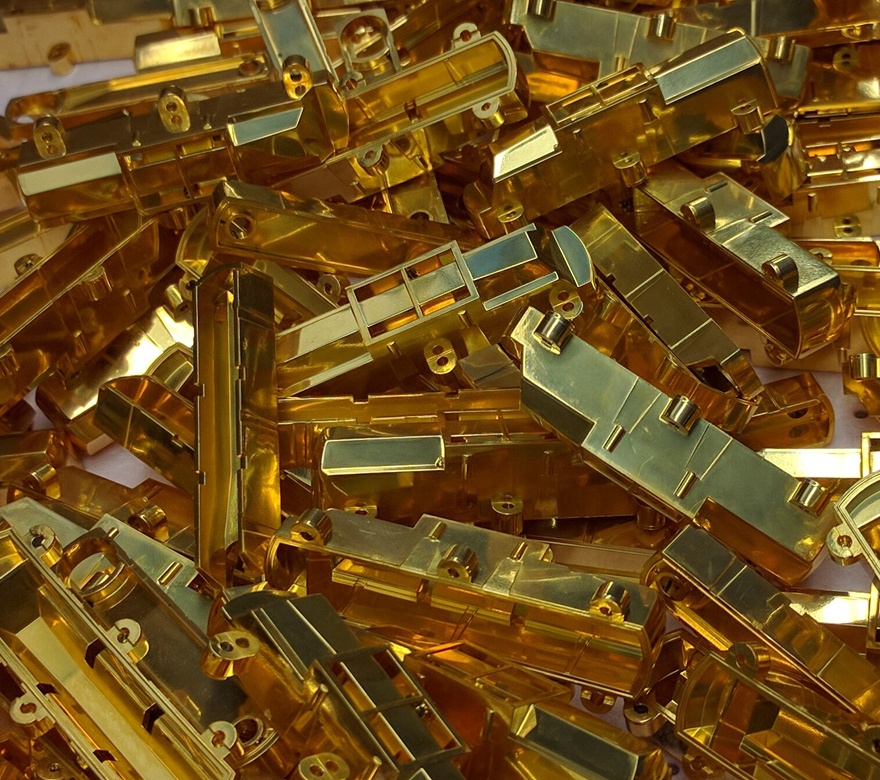

At SPC, we're proud of our ability to provide reliable and affordable metal finishing services to companies across a wide spectrum of industries. We're also regarded as a top gold plating company, as well as one of the leading silver plating companies in the industry.

The list of industries we serve includes:

SPC is an experienced industrial plating company that has been providing innovative metal finishing solutions since 1925. We offer a wide range of customized electroplating and related metal finishing services that help our industrial and manufacturing customers develop higher quality products and lower their operating costs. We're also one of the most eco-friendly metal plating companies operating today. We're constantly working to find ways to develop metal finishing processes that protect and preserve the environment.

Choose an Exotic Material:

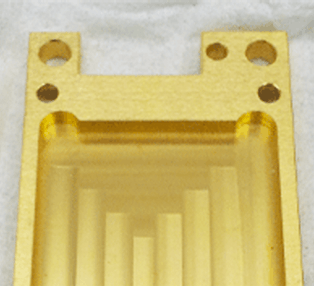

Gold Plating

Benefits

- High corrosion & tarnish resistance

- Wear resistance (fretting)

- High conductivity

- Low and stable contact resistance

- Bondable

- Solderable

Industry Uses

- Semiconductors

- Printed/Etched circuits

- Contacts/Connectors

Exotic Surfaces

- Ceramic

- Glass

- Plastic

- Refractory Metals

Metal Plating Services

You can count on us for a vast array of metal plating services, including gold and silver plating and much more. Some of our services include:

Gold

Gold is known for its glitter and glamour, but it also has significant value from an electroplating perspective.Learn More »

Platinum

This precious metal that is often considered even more "precious" than gold and silver because of its extreme scarcity.Learn More »

Palladium

Palladium is a soft metal known for its semi-bright, silvery-blue appearance, low density and low melting point.Learn More »

Rhodium

Rhodium is one of the rarest metals found in the Earth’s crust. In its metallic form, rhodium is silvery-white in color and extremely hard in composition.Learn More »

Ruthenium

An extremely rare transition metal that exhibits a lustrous, silvery-white metallic appearance. In its metallic state, ruthenium is a hard, brittle material.Learn More »

Silver

Silver is characterized as a noble metal, meaning it holds up well against chemicals and acids, offering excellent protection against corrosion, as well as low-contact resistance.Learn More »

SPC has also developed a electroless nickel plating process that is in high demand in industries such as aerospace, automotive and solar. We have perfected the process of plating on plastics, and we're one of the few companies that can successfully plate onto titanium.

Plating Onto Plastics

While plastic is harder to work with than traditional metallic materials, plating on plastic has been in practice since the 1980s as a method to improve the EMI shielding of electronic devices. Now a common industrial practice, plating on plastic is used to lend a variety of metallic properties to plastic parts for both functional and aesthetic purposes in a variety of industries, from the consumer products sector to the medical and dental industries. Either electroplating or electroless plating procedures can be used to deposit metallic layers onto plastic.

Material Capabilities:

- ABS (most common)

- Phenolic

- Urea formaldehyde

- Polyethersulfone

- Polyacetal

- Diallyl phthalate

- Polyetherimide

- Teflon

- Polyarylether

- Polycarbonate

- Polyphenylene oxide (modified)

- Mineral-reinforced nylon (MRN)

- Polysulfone

Industrial Benefits:

- Enhanced electrical conductivity

- Aesthetic improvements

- Improved surface finish

- Corrosion and wear resistance

- Chemical resistance

- Thermal resistance

- Improved structural support

Plating Materials:

- Copper

- Chromium

- Gold

- Silver

- Nickel

- Nickel alloys

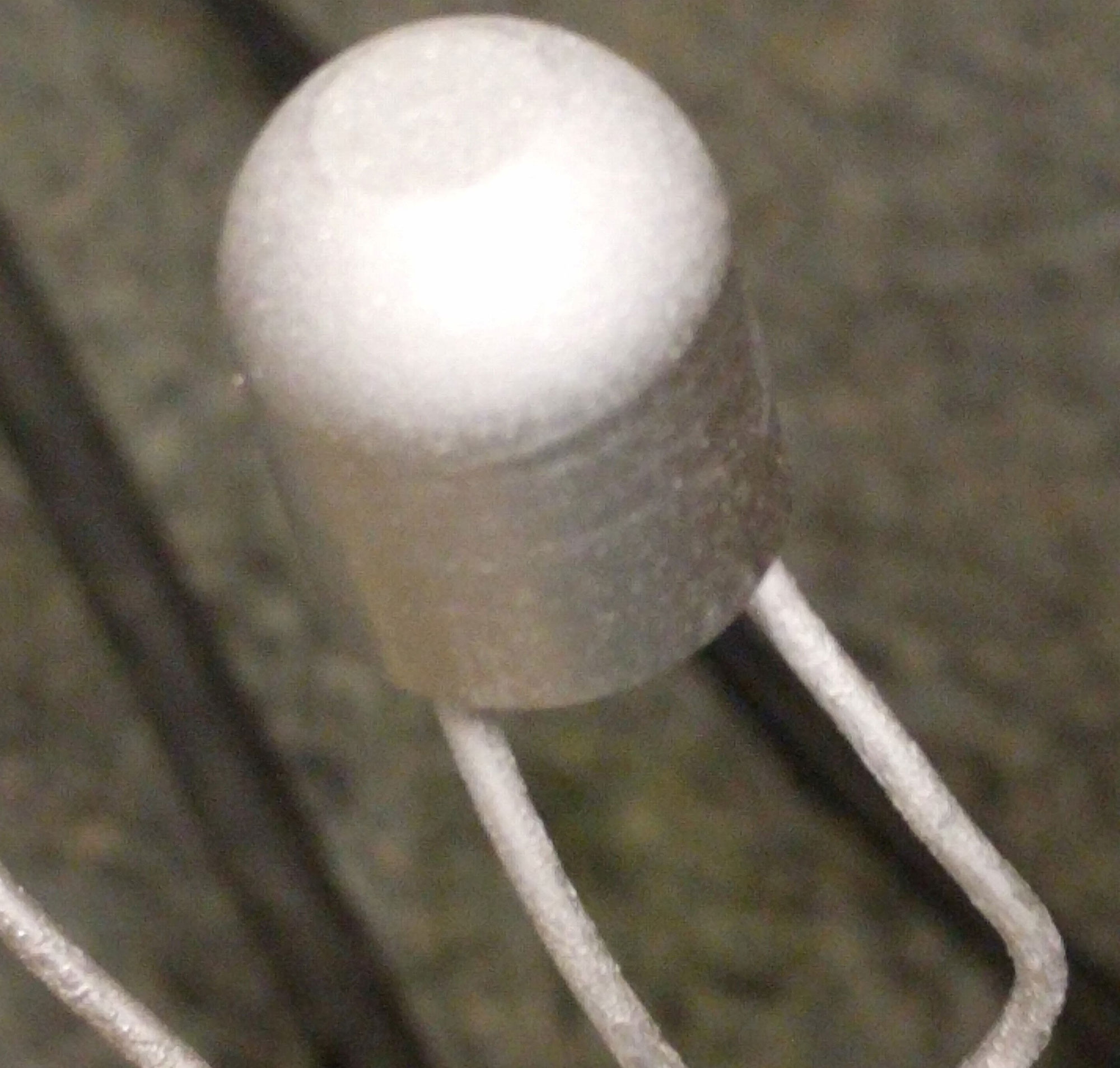

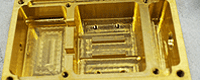

Plating Onto Ceramics

Ceramics tend to be difficult as plating substrates, especially compared to metals and other traditional materials. However, plating onto ceramic is now common practice — ceramics plated with metal are particularly popular in the electronics industry, where metal plated ceramics are often used in circuits due to the thermal resistance and improved structural integrity they exhibit. Either electroplating or electroless plating procedures can be used to deposit layers of metal onto ceramic parts.

Industrial Benefits:

- Improved strength and durability

- Enhanced electrical conductivity

- Aesthetic appeal and surface finish

- Corrosion and wear resistance

- Chemical resistance

- Thermal resistance

Plating Materials:

- Copper

- Aluminum

- Tin

- Gold

- Silver

- Nickel

- Nickel alloy

ADDITIONAL METAL FINISHING SERVICES

In addition to industrial plating, we offer the following metal finishing solutions:

- Abrasive Blasting

- Vibratory Edgebreaking

- Immersion Washing

- Mass Finishing

Comprehensive services are also available

Choosing the right industrial plating solution for your manufacturing processes can be challenging. At SPC, we don't believe in providing "one-size-fits-all" metal finishing services. Our experienced plating consultants can visit your facility to assess your operation and recommend a customized solution that fits your needs and budget. Our consulting services include feasibility studies, process evaluations, equipment design and more. With hundreds of years of combined expertise at your disposal, you can make your decision with total confidence.

LEARN WHAT OUR MANY SATISFIED CUSTOMERS HAVE TO SAY ABOUT Us

"I would like to thank you for the help you have provided us in developing an electroless nickel plating technique on an unusual substrate. The sample platings you provided show that we should be able to reach our goals. I especially appreciate your willingness to take on an unusual job, with the uncertainties that that entails...We are looking forward to working with you in the future on our plating needs."

– Robert K.

Benefits of Electroplating

-

Superior Protection

-

Provides superior protection against the harmful effects of corrosion and wear.

-

-

Aesthetic Appeal

-

Enhances the aesthetic appeal of your products.

-

-

Improved Conductivity

-

Improves electrical conductivity of certain metals.

-

-

Longer Lifespan

-

Lengthens the lifespan of the plated piece.

-

News & Insights

See all Posts

PALLADIUM VS. GOLD PLATING - WHICH OPTION TO CHOOSE?

While both are lauded in the jewelry industry for their beautiful appearances, there’s more to palladium and gold than their looks...