Overview:

Our world is continuously becoming more electronic, and devices from smartphones and virtual assistants to connected industrial equipment and smart cars are playing increasingly important roles in our lives. This high number of electronics means, among many other things, that there are lots of electromagnetic signals flying around.

Many of our devices depend on these signals to work but can also be damaged or rendered inoperable by them. Because of the growing importance of electronics, we need to protect them from these potentially damaging interferences.

There are several ways in which we do this. We can reduce the length of wires in devices to minimize the chances of interference. We can also install additional parts, such as inductors and circuit breakers, into devices that filter out interference.

Typically, though, the most effective approach is electromagnetic interference shielding, often known as EMI shielding.

What Is EMI Shielding?

EMI shielding creates an enclosure around a device or cables that block signals and protects it from interference. When referring to a type of EMI called radio-frequency electromagnetic radiation, this barrier is called RFI shielding.

What exactly is EMI? Electromagnetic interference is when two electromagnetic fields interfere with each other, causing distortions in both. Another way to describe it is a signal at a device’s receiver that you do not want.

People sometimes experience EMI in their day-to-day lives without realizing that’s what it is. For example, trying to use a hair dryer while watching TV may interfere with the TV signal. You might also hear some static coming from your car radio when using your cell phone in your car.

Sources of EMI

Electromagnetic fields can come from a variety of sources including human-made equipment that contain electronic circuits. Natural occurrences, such as lightning and cosmic noise, also emit electromagnetic fields.

A significant portion of EMI comes from ambient interference such as consumer electronics, telecom transmissions, power lines and lightning. Another source of EMI is high-powered electromagnetic pulse (HEMP) threats. This type of EMI is intentionally created by military or terrorist organizations using one of several high-powered weapons and devices designed to disable electronic systems.

Another potential source of EMI is power quality degradation issues such as sudden changes in voltage, blackouts, brownouts and power line faults. Mass transit systems also produce high levels of EMI because of the railroad or transit engine’s propulsion systems, along with other equipment, operate at high voltages. Medical devices can also cause electromagnetic fields.

Types of EMI

You can also categorize EMI according to its duration. Some EMI is continuous interference, while other kinds of EMI is classified as impulse noise.

EMI can also be classified as either narrowband or broadband. Narrowband EMI comes from intended transmissions such as those of cell phones or radios. They likely come from a single-carrier source. Broadband EMI is typically unintended and comes from sources such as power lines, arc welders and the sun. If the sun is positioned by a satellite, the noise of the broadband can temporarily block the signal. These “run-outs” only last a few minutes at a time.

Typically EMI is radiated between the two affected systems. These systems are typically more than one wavelength apart, and the source radiates the signal, which is picked up by the “victim,” the receiver that experiences the interference. Conducted EMI may occur if there is a route for conduction, such as power cables or other interconnected cabling, between the two systems.

Shielding of EMI

EMI/RFI shielding offers the ability to reduce and control these fields so that they do not cause unwanted interactions. It may be used to prevent signals from entering a sensitive system or prevent them from escaping from a noisy system. It can reduce many different types of interference including EMI from electromagnetic fields, electrostatic signals and radio waves. It can block interference coming from outside devices and can also reduce the amount of EMI a device may emit.

This shielding typically comes in the form of a plastic enclosure — the electronics housing — with a metal component that reflects or absorbs the interference.

Why We Need EMI/RFI Shielding Enclosures

EMI shielding is critical to the way we live, as it enables our electronic devices to work properly. It’s necessary for devices from consumer electronics to life-saving equipment in hospitals.

Without shielding, our many electronic devices would interfere with each other and would also be subject to interference from fields caused by natural phenomena. This EMI could damage electronics, which would be prohibitively expensive if it happened repeatedly. Even if it does not cause damage, it can prevent them from working correctly.

EMI may cause electrical problems such as burnouts, latch-ups and upsets. HEMP attacks could destroy or disable large-scale electronic systems. Power quality issues in electric utility equipment may also damage devices that are plugged in.

EMI can cause problems by suppressing a device’s internally created signals, causing ambient interference with device operation externally and lead to internal signals that prevent proper equipment performance. Shielding can help prevent all three of these impacts.

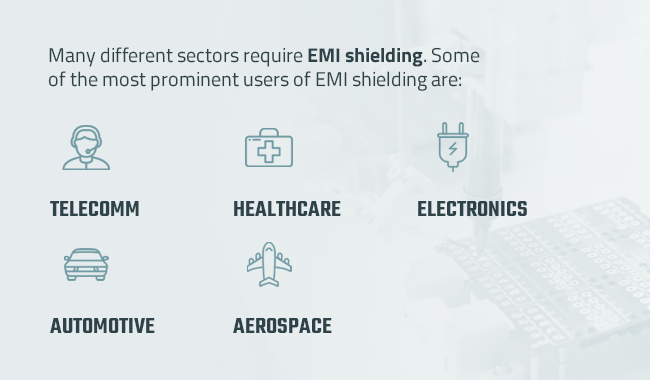

Many different sectors require EMI shielding. Some of the most prominent users of EMI shielding are:

- The Telecomm Industry: Without EMI shielding, most telecom equipment would not work correctly. Cell phones, radio and other communications rely on signals to operate. Unwanted signals, though, can cause interference and prevent a device from working correctly.

- The Healthcare Industry: Hospitals and other healthcare facilities rely on electronic equipment. Without proper shielding, EMI from cell phones, tablets and other devices may interfere with this medical equipment. This equipment often measures signals from the human body that are rather weak, so any interference could have a significant impact. It’s crucial to prevent this interference since whether a device functions properly could be a matter of life and death in a healthcare setting. The Food and Drug Administration (FDA) has put forth stringent standards for shielding for medical providers. Equipment that may be susceptible to EMI includes patient monitoring systems, MRI systems, hearing aids and implantable cardiovascular devices.

- The Consumer Electronics Industry: Consumer electronics also often need EMI shielding to function well. Shielding can help prevent interference from damaging these devices and prevent them from causing interference. This is also true for electronics used in business and industrial settings.

- The Automotive Industry: Automotive sensing equipment, as well as radio and communications equipment, require shielding. EMI can damage these components and cause them to malfunction.

- The Aerospace Industry: The aerospace industry has a similar need to prevent EMI. Airline personnel need to be in contact constantly, and interference with that can be dangerous. This is why you must turn off electronic devices or put them in “airplane mode” when on a plane.

Why Use Plastic for EMI/RFI Shielding

Typically, the most effective and common method for preventing EMI is applying shielding agents to a plastic enclosure around a device or component. You have various options when it comes to this kind of protection.

These EMI/RFI shielding agents most typically come in the form of acrylic-based sprays, but they can also be paints or other brush-on coatings. These coatings give the enclosure the necessary shielding properties.

What makes these EMI coatings for plastics effective is the fact that they contain highly pure metals that reflect interference. These metals may be copper, silver, nickel or a combination of these metals.

How much interference a shield reduces depends on numerous factors including the shielding material used and the thickness of the coating. Other factors include the size of the device to be shielded, the frequency of the electromagnetic fields in question, any holes or gaps in the shield and the mechanical characteristics of the gaskets used on the enclosure. The ideal barrier would be continuous with no gaps or holes, but, typically, this is not practical.

Additional options for achieving shielding are listed below.

Selective Electroless Plating on Plastic

Using both electroplating and electroless plating on plastics is possible. When it comes to electroless plating, you can apply the plating to the whole component or use selective electroless plating and apply it only to specified parts.

Selective electroless plating is ideal for applying a coating just to electronics housing to provide EMI shielding capabilities, but you can use it with a wide range of components. This process is used for both low-volume and high-volume applications.

An initial, critical step of the selective electroless plating process is masking, which is covering the areas that are not to be plated so that the plating does not adhere to those parts. For low-volume projects, the manufacturer may apply a tape, wax or paint to mask an area, which they remove after the plating process occurs. For higher volume orders, they may create a more permanent, custom masking fixture that they can use repeatedly.

Once masking is complete, they will spray a plating onto the parts that require plating. Then, the parts will be placed on the plating fixture and lowered into the plating solution. Based on the solution used, this process will deposit the plating onto the unmasked surfaces. The result is a uniform coating that reduces EMI.

Frequently, this process involves the use of copper and nickel, although other metals can be used as well. If copper and nickel are used, the copper may be plated first followed by a coating of nickel. In addition to blocking interference, this plating is also conductive and offers other beneficial properties as well.

Electroplating Copper-Nickel Onto Plastic

Another option for applying plating to plastic electronics housing is electroplating.

Before electroplating onto plastics, the manufacturer must take several steps to prepare. First, they clean the substrate thoroughly to ensure that no dirt or debris interfere with the electroplating process. Then, they etch it in a chromic acid-based solution. This process enhances the part’s adhesive capabilities and improves the outcome of the plating. After the etching is complete, they must neutralize any excess chromic acid.

The manufacturer then applies a solution containing palladium and tin salts to the material. Next, they coat the substrate with either copper or nickel from an electroless plating solution. This palladium-tin salt solution acts as a catalyst for the plating process when combined with the nickel or copper.

After these preparatory steps are complete, the material is ready for electroplating via barrel plating or rack electroplating.

In barrel plating, the substrate goes into a barrel-shaped cage made of non-conductive material. During the process, the barrel is immersed in an electrolytic plating solution. It contains bars in its center that conduct electrical current.

Rack electroplating involves attaching the parts to metal racks using wires, hooks, bands or other fixtures that keep the pieces in place and provide the electrical contact. During the plating process, manufacturers also submerge the substrates in a plating solution.

Benefits of Copper and Nickel Plating

When combined, copper and nickel provide excellent EMI shielding. They also have various other beneficial characteristics.

Copper provides excellent electrical conductivity as well as high thermal conductivity. It provides a durable coating that much less expensive when compared to metals such as silver and gold. You can also use copper for masking as a heat stop-off. Because of its conductive properties, it’s frequently used for electronics and on non-conductive substrates.

Nickel provides many benefits as well. It offers excellent protection from corrosion and wear. It increases the hardness of plastic surfaces it’s plated on, making them more durable. If alloyed with metals like tin and tungsten, the hardness of the nickel coating increases significantly.

Thermoplastic Compounds for EMI Shielding

Another option related to EMI shielding is the use of thermoplastic compounds, a type of polymer that becomes pliable after reaching a specific temperature and solidifies once it cools.

While these compounds have valuable properties, they cannot provide EMI shielding on their own. They need to have a metal component to accomplish this.

The most common materials used with thermoplastic compounds for shielding are carbon fiber, nickel-coated carbon fiber and stainless steel fiber. One of these materials is embedded in the plastic and serves to absorb the EMI rather than reflect it as many other shielding methods do. These materials may be referred to as conductive fillers when used in this way.

These EMI-shielding plastics have varying levels of effectiveness based on the conductive plastic’s composition and other factors. The volume resistivity and shielding capabilities of these compounded resins are closely correlated. The type of conductive filler used also has a significant impact on effectiveness.

The benefits of using these thermoplastic compounds include more design freedom due to the flexibility of the material and weight reduction, which makes it especially useful for automotive and aerospace applications.

Plating Onto Plastics for EMI Shielding

If you’re looking to plate onto plastic to enhance EMI shielding or achieve other capabilities, Sharretts Plating Company can help.

Customers have been relying on SPC for their plating needs since 1925. Over the years we’ve worked with customers from a range of industries on many different kinds of materials involving various metals. We’d love to work with you on your next plating project. We invite you to get in contact with us or request a free quote.