The biomedical industry uses a range of metal instruments, and in recent years, the prevalence of implantable medical devices has increased dramatically. From joint replacements to pacemakers, implanted medical devices are changing the world of biomedical science. A key part of these implants’ functionality involves metallic plating.

The biomedical field widely uses metal coating, and medical implants are no different. From the implants themselves to parts, plated metal pieces are commonplace. These metal finishes lend important functional qualities to the finished medical devices and implants, like corrosion resistance and biocompatibility. Of these metal finishes, platinum and palladium are some of the most valuable and practical.

What Is Platinum?

This silvery white precious metal belongs to the Platinum Group Metals, or noble metals, which also include, palladium, rhodium, ruthenium, iridium and osmium. First discovered in 1735 in Columbia on a Spanish exploration mission, Platinum is named after the Spanish word “platina,” meaning silver of little value. Over time, however, platinum came to be recognized as a highly versatile and functional metal, and is now known to be extremely rare.

Platinum derives most of its value from its highly desirable physical attributes. Highly malleable and ductile, platinum is harder than silver and highly dense, with a density of 21.45 g cm3. This makes it 75 percent denser than palladium and 20 times as dense as water. It’s also highly resistant to corrosion, oxidization and heat, and so it’s an excellent choice for acidic and organic environments. This makes it highly biocompatible — unlike metals such as nickel or copper, platinum is inert in the human body, making it hypoallergenic and biocompatible.

These properties also make platinum highly desirable for a broad range of industries, especially the automotive industry. And platinum is an ideal metal for biomedical applications.

What Is Palladium?

Palladium is often compared to platinum, as it is a similar silver-white color and belongs to the platinum group of metals Though it is often confused for platinum, palladium is an entirely different material. British chemist William Hyde Wollaston discovered palladium in the early 1800s and named it for the Pallas asteroid. Mostly produced in Russia and South Africa, palladium has found wide use as a platinum substitute, primarily due to their similar physical attributes.

Palladium is about 40 percent lower in density than platinum, with a density of 12.02 g cm³. It also has a lower melting point and lower weight by volume, and is more ductile than platinum. However, these differences do not affect the machinability of palladium compared to platinum significantly. Also, like platinum, palladium is resistant to corrosion and oxidization, making it inert in organic environments. This means it is biocompatible in both soft tissue and bone environments and is hypoallergenic.

These properties make palladium a highly desirable material to replace platinum, especially since the material is lower in cost than platinum due to its greater abundance. It also makes palladium a great choice for medical applications.

How Does Platinum Compare to Palladium?

Platinum and palladium are often mistaken for one another, which is understandable considering their many similar physical and chemical properties. Some of their shared traits include:

- Color: Both platinum and palladium share a silvery white color. This makes them desirable cosmetic finishes for many products.

- Nonporous: Both platinum and palladium are nonporous metals, meaning that they form a uniformly smooth surface when plated onto another material. This poses a great benefit to biomedical applications where porous surfaces are more prone to bacterial adhesion and increase the chances of infection in implants.

- Mechanical Properties: Both platinum and palladium are malleable, ductile and relatively hard, especially when compared to other precious metals, like silver. Both also tend to retain these mechanical properties after high-temperature brazing.

- Conductivity: Platinum and palladium serve as good electrical and thermal conductors, leading to their popularity in electronics manufacturing applications.

- Corrosion Resistance: Both materials are resistant to several types of corrosion, including acid corrosion and oxidation. This means they’ll withstand most environments without sustaining significant damage or chemical alteration.

- Biocompatibility: With their strong resistance to corrosion and their inertness in organic environments, both platinum and palladium are highly biocompatible and hypoallergenic materials. This means these metals do not corrode or release potentially allergenic materials when kept in constant contact with soft tissue or bone.

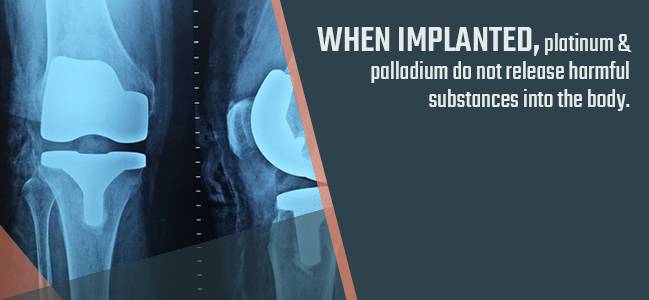

- Radiopacity: Platinum and palladium also happen to be radiopaque, meaning they block radiation. This means platinum and palladium materials will show up in X-ray images, making them easy to spot with standard medical imaging devices during treatment.

Differences Between Platinum and Palladium

While platinum and palladium are nearly identical in appearance and react to similar chemicals and elements, they do have several key differences. These differences mostly come down to density, melting point and price:

- Density: Platinum is 75% denser than palladium and 20 times as dense as water, making it slightly more durable when manipulated. This also means that the material is much heavier in comparison to palladium.

- Melting Point: Platinum’s high density also contributes to its higher melting point, coming in around 3224 degrees F. This extremely high melting point makes platinum more desirable for intense heat applications.

- Price: Platinum’s scarcity has made it a higher-priced metal for the past several decades, running about 1.5 times more than palladium in 2015. Because of this price difference and the physical and chemical similarities between platinum and palladium, many industries have come to think of palladium as the lower-cost alternative.

While palladium is largely similar in functionality to platinum and comes at a lower cost, it is still slow to overtake platinum in the market. Much of this has to do with palladium’s late start in the marketplace — many of palladium’s commercial applications came to light long after platinum had become well established in various industries. Despite these factors, both metals are gaining traction in a variety of industries.

Today, companies employ platinum and palladium in the production of numerous components. Plating with these materials is especially popular, particularly for automotive and electronic applications. However, the most innovative applications for these metals and their alloys arise in the biomedical industry.

Biomedical Benefits of Platinum and Palladium

The physical and chemical properties of platinum and palladium make them ideal for biomedical applications. As whole pieces, they can form into nearly any shape and size. As metal coatings, however, they can accomplish even more. Platinum and palladium electroplating results in a thin layer of material between 0.5 and 5 microns thick, depending on the application, which is enough to lend biomedically beneficial properties to the material base. Some of these properties include:

- Chemical Inertness: Platinum and palladium are chemically inert, meaning that they do not chemically react with most naturally occurring environments and chemicals. This also applies to the human body — when implanted inside the body, platinum and palladium do not release harmful substances. Other metals, like copper and nickel, can release molecules that cause allergic reactions. When plated, palladium and platinum can lend these properties to implants and medical devices, protecting the human body from otherwise harmful implanted materials.

- Electrical Conductivity: Both materials are excellent electrical conductors, making them ideal for electrodes in stimulation devices. This property also lends to an object with plating.

- Radiopacity: Because platinum and palladium are clearly visible on X-rays, an implant covered with these materials will also gain this radiopacity. This makes platinum and palladium useful for implants that need tracked during treatment processes.

- Strength: The durability and hardness of palladium and platinum are also positive points for their applications in biomedical devices. They can add strength to a component of an instrument or implant, which can be an important quality for implants that regularly undergo stress, like joint replacement implants.

These benefits have led companies to seek platinum and palladium for some biomedical plating applications.

Biomedical Applications of Platinum Coatings

Platinum’s inherent biocompatibility makes it valuable for manufacturing medical implants and prostheses. By plating these devices with platinum, manufacturers protect the implant from corrosion and protect the patient from non-biocompatible materials. These chemical and physical properties make platinum an ideal pick for many applications, including:

- Electrodes: Platinum’s electrical conductivity makes it a good choice for medical machinery electrodes. You can use these electrodes in several applications, such as oxygen sensors, pacemakers, implantable defibrillators and electrophysiology catheters, among others. Partially platinum plated biomedical devices are particularly common in this application.

- Dental Implants: Companies have long made dental caps and implants with precious metals, including platinum. Though the dental industry still relies on platinum, most dental implants are now made with titanium and titanium alloys.

- Surgical Implants: Platinum alloys plate stents and catheters, lending rigidity to these implants. This plating also helps improve the radiopacity of the implants, so you can see them in X-rays when checking for implant movement.

- Orthopedic Implants: Today’s aging populations need hip and knee implants, and platinum often plates them. Though most companies construct implants with base materials like stainless steel, cobalt-chromium and titanium, these metals often require additional plating to combat friction and long-term wear. Platinum often serves as a good material for such applications. Platinum is particularly favored as a surface plating for titanium hip and knee joint replacements.

The primary limiting factor for using platinum in biomedical devices is cost — while some applications require platinum for its high density and somewhat better manufacturing workability over palladium, many manufacturers choose to defer to the cheaper of the two options.

Biomedical Applications of Palladium

Palladium is as biocompatible and workable as platinum, making it equally usable for medical implants. With similar resistance to corrosion and strength, palladium plated biomedical devices are used in several applications, including:

- Dentistry: The dental industry has used palladium and its alloys for over two decades, resulting in strong dental implants with good corrosion resistance in oral environments. Though mostly used for crowns and bridges, companies also plate palladium onto titanium implants to protect the surface of the base material.

- Temporary Implants: Palladium alloys provide an alternative to platinum alloys when plating catheters and components of other temporary implants. The material helps improve the outer rigidity of the implant, while also improving radiopacity for X-ray check-ups. These properties make it much easier to check up on patients with temporary implants to make sure that they don’t move excessively.

The use of palladium in biomedical devices is widespread, but is currently not common in orthopedic implants, since platinum is much more firmly established in that area. In most other applications, you can use palladium and platinum with near-equal efficacy and reliability. In these cases, manufacturers may prefer palladium and its alloys over platinum for the sake of cost.

Platinum Vs. Palladium in Biomedical Devices

When choosing to plate an implant or implant component with palladium or platinum, most medical manufacturers defer to platinum, the more established of the two. Platinum has been in use in the biomedical industry for 40 years, while palladium was introduced as a viable biomedical option more recently.

While this is a short delay, it has resulted in palladium getting a slower start in the biomedical field. Experts do expect research in palladium applications will eventually bring palladium on equal footing with platinum, but it will be several more years before the two are truly interchangeable plating options.

However, outside of this difference in preference, there are few meaningful variances between the materials. Though the disparities in density and melting points are substantial, they make little difference from a manufacturing or biomedical standpoint. With all other factors equal, the major factors in platinum’s greater usage are palladium’s lower price and platinum’s establishment in the field.

These leave the decision largely in the customers’ hands. Platinum is the preferred choice for companies that want the more established option with a broader range of applications. It’s also the better pick for medical manufacturing companies looking to plate orthopedic implants.

However, when price is the primary determining factor, palladium often wins the decision. This dynamic will likely change in the future as palladium’s applications become more widely appreciated and medical technology advances.

Sharretts Plating Company Can Help With Your Medical Device Coatings

If you’re looking for a company with extensive experience in both palladium and platinum plating processes for the biomedical industry, SPC can help. SPC has worked with medical device coating projects of all types and sizes and is one of the few metal finishing companies that has mastered the art of plating onto titanium.

With almost a century of experience in metal finishing techniques, SPC is the best resource available when you need high-quality medical metal finishing. We have the extensive equipment, facilities, resources and experience needed to meet the needs of any medical manufacturing project, and our staff will work with you to develop a finishing process specifically for your medical application.

Even better, we are an ISO-certified and progress-focused organization, meaning we make quality a priority. In short, we guarantee the best results possible every time.

Contact SPC today to learn more about palladium and platinum plating options for the medical industry and how SPC can help you achieve the best medical-grade coating possible. Get in touch for your free, no-obligation quote or schedule an on-site consultation to discuss options that fit your needs and budget.