If your business involves the manufacturing of products consisting of any type of metal, then you undoubtedly understand the importance of metal finishing. In simple terms, metal finishing is the process of applying a metal coating or other treatment to the surface of a metal part or component. This part or component is referred to as a substrate. Metal finishing can be a physical, chemical or mechanical process. In general, metal finishing is used to protect, enhance the appearance of, and/or improve the performance of the product.

The term “metal finishing” is actually somewhat of a misnomer, as it encompasses non-metallic surfaces and materials as well. For instance, a metal coating can be applied to a plastic substrate. Metal finishing is now often used as a generic term to describe the final phase in the manufacturing process of metallic or non-metallic products.

Specific Purposes of Metal Finishing

Metal finishing occurs in a wide range of industries, including aerospace, electronics, jewelry, consumer products, hardware and many others. Metal finishing is specifically used for the following purposes:

- Greater corrosion resistance

- Increased surface thickness

- Increased strength and durability

- Enhanced appearance

- Increased solderability

- Improved electrical conductivity

- Increased electrical resistance

- Greater chemical resistance

- Increased potential for vulcanization — the process of converting rubber or polymer to more durable materials

- Increased surface hardness

- Improved adhesion

- Increased torque tolerance

- Greater wear resistance

Which Metal Finishing Process Is Right for You?

Metal finishing is not one single process, and it can be executed in multiple ways. Sorting through the various metal finishing options can also be confusing. That’s why we put together an overview of some of the more commonly applied metal finishing processes, so you can choose the ones that make the most sense for your company.

Industrial Plating

Industrial plating is the process of depositing a thin coating onto the surface of a substrate. The most common form of industrial plating is electroplating, which is primarily used to build surface thickness. Also known as electrodeposition, electroplating is accomplished by sending an electric current through an electrolyte solution. This is referred to as a bath, which contains the metal substrate along with dissolved ions of the metal used as the coating.

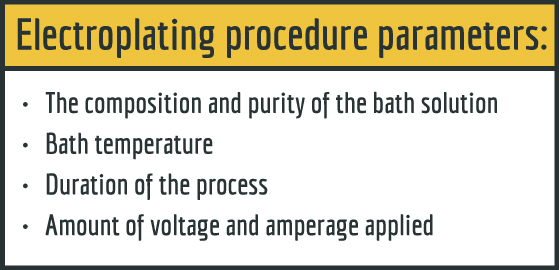

The electroplating procedure is regulated by tightly controlling various parameters throughout the process. These parameters typically include:

- The composition and purity of the bath solution

- Bath temperature

- Duration of the process

- Amount of voltage and amperage applied

The process can involve rack plating, which is where large, fragile or complex parts are hung on a rack and immersed into the plating bath. Another option is barrel plating, which involves smaller parts being placed inside a barrel that is rotated through the plating solution.

Standard Industrial Plating Types

Electroplating can be further classified by the type of metal that is used to provide the coating. Standard metals include tin, copper, zinc and nickel, as well as various alloys. Let’s take a closer look at each metal, including their plating benefits:

- Tin — Tin is a relatively soft, malleable metal that is available in abundance. Because tin is so readily available, the tin plating process is often more cost-effective than when using other metals. The tin plating process, also known as “tinning,” can be the best option when affordable corrosion protection is desired. Additionally, tinning can be precisely controlled to achieve a matte, semi-bright or bright appearance.

- Copper — Most of us know that copper is an excellent conductor of electricity. Thus, copper electroplating is a preferred metal finishing choice in the manufacturing of electronic circuit boards, semiconductors, and other electronic parts and components. In addition to being highly conductive, copper offers improved adhesion.

- Zinc — Like tin, zinc is a readily available element, which makes zinc plating a relatively inexpensive metal finishing option. Zinc’s primary benefit is that it offers excellent protection against corrosion. Zinc plating is primarily used to increase corrosion resistance on smaller metallic parts such as nuts, bolts and screws.

- Nickel — Nickel is a strong, lustrous metal that is often used as a base coat prior to plating with a precious metal such as gold or silver. Nickel plating can harden the surface of the substrate, which increases wear resistance. Nickel also provides superior protection against corrosion.

Electroplating With Precious Metals

Unlike standard metals that can normally be found in abundance, precious metals are relatively rare. Consequently, precious metals tend to have a higher economic value. Precious metals such as gold, silver, palladium, rhodium and ruthenium contain properties that are beneficial for industrial plating purposes:

- Gold: Gold’s obvious aesthetic appeal makes gold plating a common practice in the manufacturing of fine jewelry and other products where appearance is essential. Electroplating gold also increases the substrate’s resistance to corrosion and tarnishing. Gold also has relatively high electrical conductivity and stable contact resistance, which makes it a popular plating choice for electrical components such as semiconductors and connectors.

- Silver: Silver is a ductile, malleable precious metal. Electroplating silver onto a substrate is sometimes preferable to electroplating gold due to silver’s hardness advantage. Silver’s key plating benefit is its extremely high electrical and thermal conductivity. The silver plating process can then be regulated to achieve either a matte or bright finish.

- Palladium: Electroplating palladium is often chosen as an alternative to electroplating gold or platinum due to palladium’s lower cost. Palladium is known for its ability to absorb hydrogen, which can reduce the likelihood of the occurrence of hydrogen embrittlement. Palladium is also lighter than gold and offers comparable corrosion resistance.

- Rhodium: A member of the platinum family, rhodium is a relatively rare precious metal that is known for its hardness and durability. Rhodium also exhibits a reflective, silver-white appearance that makes it a popular choice for plating fine jewelry pieces. Because of its scarcity, plating with rhodium may be a cost-prohibitive process for many manufacturing operations.

- Ruthenium: Another type of metal found in the platinum group, ruthenium is an extremely hard material with a lustrous gray appearance. Because of its density, ruthenium works well for metal finishing applications that require additional wear resistance, especially when alloyed with platinum or palladium. A ruthenium coating also provides excellent protection against scratching and abrasions.

- Platinum: Because of both durability and aesthetic appeal, platinum is a highly sought-after precious metal. It’s an ideal plating material for various industrial applications, and it’s used in the production of about 20 percent of all consumer products despite being rarer than both silver and gold. It offers high resistance to tarnishing and corrosion and can stand up to both the passage of time and high temperatures. Its high strength makes it ideal as a coating for less sturdy materials.

Electroplating Alloys

While all of the metals mentioned above can be plated individually, they are often alloyed with other metals. Alloying can enhance the electroplating process by introducing additional benefits that one metal may not be able to provide alone. It may also negate the potentially harmful properties of one of the metals. Common electroplating alloys include:

- Palladium/nickel — Frequently used in a variety of electronics manufacturing applications, a palladium/nickel alloy reduces the stress of the deposit.

- Palladium/cobalt — A relatively new metal alloy, palladium/cobalt is gradually replacing palladium/nickel in various electronics manufacturing processes.

- Tin/lead — A tin/lead alloy can reduce the occurrence of tin “whiskers,” which are sharp metal strands that often appear after tinning and can cause significant damage to electronic components.

- Zinc/nickel — A zinc/nickel alloy offers greater protection against corrosion than zinc plating alone. It’s also capable of withstanding higher temperatures.

Electroplating on Light Metals

Some metal finishing projects require lighter metals to minimize the weight added to the workpiece — but without sacrificing strength and wear resistance. There are several lightweight metals with lower densities that provide the ideal plating solution for various parts and components in industries such as aerospace, medical and automotive. These metals offer a high strength-to-weight ratio along with good corrosion resistance and several other useful properties:

- Titanium: Titanium is a hard, silver-gray metal that provides superior corrosion resistance when plated onto aircraft parts, as well as various defense and chemical manufacturing applications. It can withstand the corrosive effects of seawater and many chemicals. Titanium is also biocompatible, making it safe to use as a coating on medical implants.

- Aluminum: Aluminum and aluminum alloys have been a popular metal choice for decades. Aluminum is soft and relatively lightweight, but is also deceptively strong and durable. You can find aluminum-coated parts in automobiles, food and beverage containers, aircraft and many other common items.

- Magnesium: A member of the alkaline earth metal series, magnesium is less dense than aluminum but delivers the ideal combination of strength and lightness. Magnesium also resists heat, making it a preferred choice when manufacturing automotive engine blocks and cylinders.

Electroplating on Titanium

As mentioned, Titanium is a lightweight, durable metal that is silver in color. Titanium’s high strength-to-weight ratio makes it suitable for aerospace applications such as the manufacturing of aircraft and missiles. Titanium cannot be electroplated onto other metals with current science and aqueous solutions. However, plating onto titanium can be accomplished by alloying with nickel to increase a substrate’s resistance to corrosion, or with platinum to improve its appearance.

Electroplating on Plastic

Electroplating is not strictly limited to metal-on-metal plating applications. Plating a metal onto plastic can be difficult to execute properly, but it’s an extremely useful process. A primary reason to apply a metal coating onto a plastic or other non-metallic substrate is to make the surface of the object electrically conductive.

Copper is usually the metal of choice for achieving this purpose. Plating on plastic can also improve the appearance of an object or enhance its resistance to corrosion. It can even harden the surface and increase its durability.

Electroplating on Glass

Because of its fragility, it may be necessary to apply a protective coating to a glass substrate. Plating onto glass will metalize the surface, making it more durable. Plating can also make a glass workpiece electrically conductive, which provides greater compatibility with other metal finishing techniques. Glass is among the most challenging materials to plate and typically requires the application of various surface preparation techniques.

Plating is rapidly becoming a preferred glass finishing technique in the emerging biotechnology industry. The process usually entails electroless plating, which relies on an autocatalytic reaction to apply the coating instead of electricity. The electronics industry also uses electroplating on glass for parts such as high-frequency radio filters and interposers.

Electroplating on Ceramics

Because ceramics are entirely non-metallic in composition, they often require the application of a metal material depending on the industry they’re being used in. For instance, a ceramic substrate can become more suitable for electronics manufacturing applications if it has been metalized, as it can then conduct electricity and also gains strength and durability. Since ceramics can naturally withstand high temperatures, the combination of their inherent qualities with those added from a metal or alloy makes them ideal for certain electronic applications.

To complete the process of electroplating on ceramics, metal coating is usually applied via electrodeposition after the surface of the substrate has been prepared to promote coating adhesion. Electroless plating, often with nickel or copper, is also sometimes used to coat ceramic substrates.

Electroplating on Refractory Metals

Refractory metals represent a special category of materials that provide exceptional protection against wear and heat — and they’re also among the most difficult to plate successfully. SPC offers premium metal finishing services for these refractory materials:

- Molybdenum: The most commonly used refractory metal for manufacturing purposes, molybdenum and its alloys can provide additional strength and wear resistance to steel workpieces.

- Tungsten: Tungsten’s remarkable heat resistance makes it a preferred choice when manufacturing products like heating elements, radiation shields and electrical contacts.

- Niobium: Niobium is often alloyed with materials such as iron and nickel. Niobium is the least dense of the refractory metals, making it suitable for applications requiring enhanced protection with the least amount of added weight.

How to Select an Electroplated Finish

When selecting an electroplated finish, it’s important to consider a variety of factors, including:

- Material of the substrate

- Purpose of the finish

- Budget

- Relevant standards or regulations

The substrate is one of the most important factors to consider when choosing a finish, since it will influence the choice as well as the type of plating process required. If your substrate conducts electricity, you’ll be able to achieve almost any metallic finish using electroplating. However, if your substrate is made of a plastic, ceramic or hybrid material, it will first need to be given an electroless nickel coating before electroplating. This extra step could influence your budget as well as your finish of choice.

Another important factor to consider is the purpose of the finish. Will it need to stand up to intense environmental conditions, or is it purely decorative? Depending on the intended use of your product, different finishes can provide different benefits. A copper finish, for example, might be selected to conduct electricity, whereas a zinc-nickel alloy plating might work to protect against corrosion. Consider how the properties of the finish could enhance your product before making a final decision.

Your budget may also influence finishing decisions. Industrial metals such as tin, copper and zinc are more affordable than precious metals like gold, silver and platinum. Even in small quantities on the surface of a product, precious metals can be expensive. On the other hand, the purpose of the coating could justify higher spending. Weigh function against cost as you make your decision.

Finally, you may also need to consider environmental regulations and industry standards as you choose a metal finish. The Environmental Protection Agency and other organizations may limit the amount of certain metals released into the air or water. Furthermore, industries may have certain finishes treated as standards.

Materials that need to endure harsh conditions may need to be coated with finishes that resist wear and remain where they’re meant to be — solidly attached to your product. Current regulations and best practices in your industry, as well as the purpose of your product, could determine what kinds of finishes are appropriate.

Choosing a metal finish is an enormous task, especially with so many finishes available, but making a good decision in this step can boost the quality of your product. It’s important to ensure that the metal finish you choose performs well and fits within your budget. At SPC, our expert staff can advise you on the best electroplating finishes for your needs.

Electroless Plating

The industrial plating process does not always require the use of electricity. Instead of an electric current, electroless plating relies on a chemical reaction to deposit the metal onto the surface of the substrate. With electroless plating, the deposition of the metal coating typically occurs at a much slower rate than during electroplating. The key benefit is that the coating can be applied more smoothly and evenly. The electroless nickel plating process can also be simpler to execute, and the absence of electricity can reduce the overall process costs.

Nickel is the metal that is most commonly used in electroless plating. Electroless nickel is compatible with a wide variety of base materials such as aluminum, stainless steel, copper, zinc die-cast and brass. An electroless nickel coating may also be applied on plastic as a preparatory step prior to electroplating on plastic. A recent development in the world of electroless nickel plating is a black electroless nickel process that provides a black nickel coating, which is desirable to many companies in industries such as aerospace and firearms manufacturing.

Passivation

Another widely applied metal finishing process is passivation. As the term implies, the purpose of the passivation process is to render the material “passive” — or less susceptible to damage caused by environmental factors such as water or air. Passivation is often implemented as part of the post-treatment zinc or zinc-alloy plating process as a means of preventing the onset of white rust. It is also used for descaling and cleaning of stainless steel parts for enhanced corrosion resistance.

Anodizing

Primarily used to convert the surface of an aluminum object to aluminum oxide, anodizing can also deposit a thin, protective film on other nonferrous standard metals. By altering the molecular composition of the surface, anodizing can provide important benefits such as increased corrosion resistance, reduced impact of normal wear and tear, and a stronger, harder finish. While an anodized finish is naturally colorless, dyes in various colors can be added for applications requiring aesthetic appeal.

Vacuum Impregnation

If your operations involve any type of metal casting process, you’re undoubtedly familiar with the issue of leakage caused by porosity. Vacuum impregnation is a process that can reduce or eliminate occurrences of micro and macro porosity through the precise application of vacuum pressure. Vacuum impregnation works by removing the air that is present as the casting solidifies, and injecting a sealant to form an airtight seal.

Abrasive Blasting

Abrasive blasting also offers the advantage of combining surface finishing and cleaning into one process, which can save time and money. The abrasive blasting process involves the high-pressure propulsion of a blasting medium against the surface of an object. This can remove contaminants and produce a smooth, clean finish. Abrasive blasting can also be used as a surface preparation treatment prior to plating, painting or coating. It can even be applied to help alter the shape or increase the surface area of an object.

Shot Peening

Shot peening is somewhat similar to abrasive blasting in that the process uses high pressure to propel the medium (shot) onto the surface of an object. The key difference is that, instead of abrasion, shot peening relies on plasticity — which results in a change in the mechanical properties of the surface. By creating beneficial “compressive stress,” shot peening can reduce the occurrence of micro-cracks on the surface and significantly increase fatigue life. Common shot peening applications include edgebreaking, cleaning and appearance enhancement.

Mass Finishing

Mass finishing is a highly complex process that is used to provide simultaneous bulk polishing of a high volume of smaller, more technical parts. Also known as mechanical surface finishing, the process involves the use of a vibratory or tumble finishing technique and a carefully selected medium. Processes that are compatible with mass finishing include degreasing, descaling, rust removal and general surface cleaning. The key benefit of mass finishing is that it enables the production of a large volume of uniform parts at a relatively low cost.

What to Consider When Choosing a Metal Finishing Process

It’s important to take a number of factors into consideration when determining which metal finishing process best meets your requirements. First, consider which process type will best help you achieve your specific goal, whether it’s corrosion protection, improved appearance, electrical conductivity or another outcome.

Another important consideration is the length of time it takes to complete the finishing process. Cycle times can vary greatly from one process to another, and factors such as substrate, part size and job volume will also have a major impact. You’ll need to be sure that the selected process connects with your production schedule.

Of course, cost will also play an important role in your choice. When considering cost, you should think about the long-term as well as short-term costs. Remember that while some metal finishing processes may require a higher up-front expenditure, they may also result in significant cost benefits in the form of shorter cycle times or higher quality.

Sharretts Plating Company: An Experienced Metal Finishing Solutions Provider

Experience should be an important factor as you begin evaluating metal plating companies. Sharretts Plating Company has nine decades of experience in providing cost-effective metal finishing solutions for companies in all types of industries. We offer all of the industrial metal plating and finishing services mentioned in this post. Our team will work with you to develop a customized metal finishing process that can reduce your operating costs, help you meet your production goals and provide better service to your customer base.

Contact SPC today to learn more about our vast array of metal finishing services. Be sure to sign up to receive our informative e-newsletter.