Quick Links:

Platinum Plating Capabilities | Platinum Plating Methods | Platinum Plating FAQs

PLATINUM PLATING

Like other precious metals, platinum (Pt) offers durability, longevity and value to products that use it for plating. With a finish of platinum on the exterior of a part, it gains the benefits of the metal without the cost of creating a solid part using this material.

PLATINUM PLATING CAPABILITIES

We offer many plating capabilities with this metal, including means of customizing your order based on the following:

- Thicknesses:We can create thicknesses of coating ranging from 0.125 to 25 microns.

PLATINUM PLATING METHODS

For metal finishing with precious metals, we frequently use the following techniques:

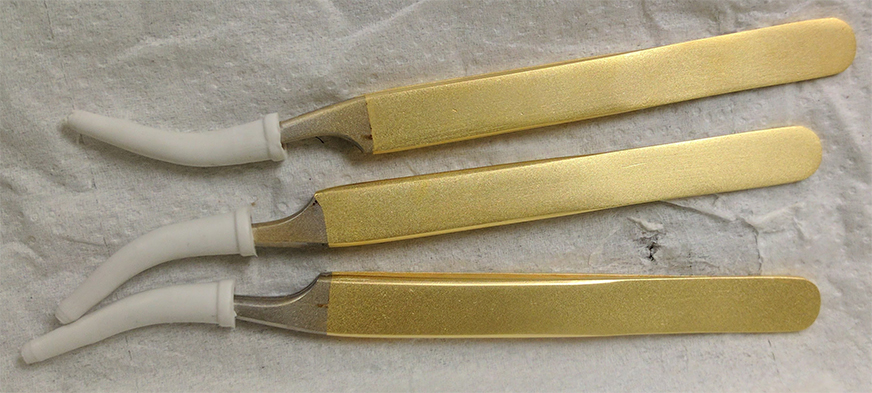

- Rack plating: This method fixes delicate or large pieces to a rack before submerging the system into an electroplating bath.

- Barrel plating: By using the barrel plating method , we can plate a small or large quantity of parts in a barrel to create an even coating. The parts must have a small enough size to fit in the barrel and cannot sustain damage from the barrel turning during the process.

Request a free quote

For Platinum Coating

PLATINUM PLATING FAQS

Due to the nature of this precious metal coating's frequent use in products – 20% of consumer products use this metal – many people have concerns about this metal and how plating with it affects a project. If you have questions about our platinum plating and our various capabilities, we have answers.

1. WHAT IS PLATINUM PLATING?

Platinum plating occurs through electroplating, which uses electricity and an electrolyte solution to deposit the ions of this metal onto the surface of the targeted base. The thickness of the deposit depends on the solution used and its processing time.

2. WHAT IS THE PLATINUM PLATING PROCESS?

The process for electroplating with this metal depends on whether your parts need a rack or barrel plating. While the setups for these methods differ, the electroplating process follows the same steps.

For rack plating, we affix large or delicate parts onto racks or build customized units to hold them. These racks keep the parts in place during the electroplating process while exposing the greatest surface area to the solution.

When barrel plating, we can coat large or small quantities of durable parts by rotating them in a barrel in the electroplating solution.

To electroplate, a negative charge passes through the parts connected to the rack or via each other in a barrel. A positive charge goes to a piece of platinum alloy. The positive charge pulls ions of the metal from the donor piece. The negative charge draws the ions through the electrolyte solution onto the surface of the parts. Leaving the parts in the solution longer produces a thicker coating. If you start with non-metal parts, they may require electroless nickel plating to create a surface that will hold a charge for electroplating.

3. WHAT'S THE COST OF PLATING WITH PLATINUM?

Plating with this metal costs can vary because pure platinum is extremely rare in nature and requires processing to remove any impurities. Sometimes, it can cost more than other precious metals due to its scarcity and manufacturers' high demand. However, supply and demand can affect the price, and subsequently, plating with it.

As a precious metal, platinum is more expensive than more common coatings, such as nickel, but when you need the benefits of platinum coatings, the extra cost is a worthwhile investment.

4. WHAT ARE THE BENEFITS OF ELECTROPLATING WITH PLATINUM?

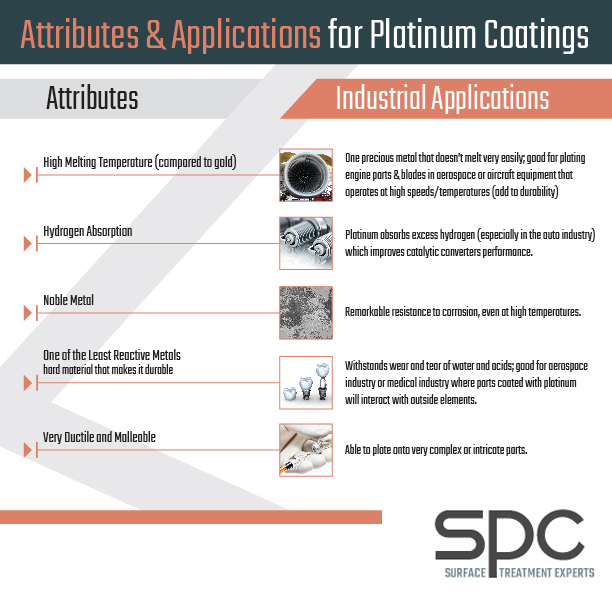

Platinum offers numerous benefits to products that use it as a coating. These benefits include the following:

- Corrosion protection: The prime reason many choose this metal for a coating is its ability to create a corrosion-resistant surface. A thorough coating protects the substrate from rust.

- Aesthetics: When using platinum as a silver coating, it does not affect the aesthetics of the silver significantly because both metals have a similar appearance. Though this metal's appearance enhances the aesthetic appeal, it has more uses than just making things look good. We do not do coatings for only aesthetics.

- Conductive: Platinum creates a conductive surface that allows for its use in electrical parts.

- Absorbs hydrogen: The automotive industry once preferred this metal for its use in catalytic converters to absorb hydrogen from the exhaust. Now the industry uses palladium, but this metal's hydrogen absorption abilities remain important.

- Prevents tarnishing: Unlike silver, which can tarnish, platinum cannot, making it an ideal coating for silver products that need added protection from the elements.

- Resistant to heat: Parts that undergo exposure to extreme heat may benefit from a platinum coating. Pure platinum has a melting point of 3,224° F, making it ideal for parts used in high temperatures.

- Wear-resistant: Abrasion can wear off some types of coatings, but platinum holds up to many sources of wear, including from environmental conditions and use.

- Increases thickness: You can choose a thicker platinum coating to add bulk, size and longevity to your part.

- Increases hardness: Platinum ranks 4 to 4.5 out of 10 on the Mohs Scale of Hardness. This makes it harder than silver and gold. By plating with platinum, the substrate receives a more durable surface.

- Promotes adhesion: Depending on the final use of the product, you may use this metal as an intermediate layer to allow for better adhesion of paint or a top coating of another metal.

- Magnetizes: Platinum-cobalt alloys are known for making a surface magnetic.

5. WHAT ARE THE APPLICATIONS OF PLATINUM PLATING?

The use of platinum plating is crucial for many industries. These industries include:

- Medical

- Automotive

- Manufacturing

- Energy

- Aerospace

Specific uses within these sectors exhibit this metal's ability to perform in extreme conditions without tarnishing, corroding or melting.

Medical implants made of titanium may use a platinum coating. Adding platinum prevents corrosion and bacteria growth on the implant. A metal coating also extends the life of the part. Due to titanium's nature, not all finishing materials will adhere to it. Platinum is one of the few that will, but the complex process required for plating with this metal onto titanium means only a handful of companies offer it. SPC is one of those businesses with the capabilities and expertise needed for plating onto titanium.

Industrial crucibles used for mixing chemicals need to stand up to wear from multiple sources. Chemical reactions that produce heat could damage uncoated surfaces of industrial crucibles. The inert, heat-resistance of platinum makes it an ideal coating for interior surfaces of mixing crucibles used in industrial chemical processing.

Gas turbine engines produce high levels of heat. Part of the design of these engines is the thermal barrier coating (TBC) that protects the engine from corrosion and heat. Platinum frequently is a material of choice for the TBC due to its durability, heat resistance and corrosion protection.

6. WHAT ARE THE ALTERNATIVES TO PLATING WITH PLATINUM?

Other members of this metal's family offer alternatives to plating with platinum. These family members include the following related metals:

- Palladium

- Rhodium

- Ruthenium

The metals in this family have very similar chemical, physical and mechanical properties, making them interchangeable for many plating projects.

DISCOVER OUR PLATINUM PLATING SERVICES AT SPC

Quality is our priority at SPC. Since 1994, we have served as an ISO-certified plating provider with a commitment to high standards. For more information about SPC, our plating services or our platinum coatings, in particular, contact us. If you want to get started on your metal coating project, submit our free quote form by letting us know how we can help you.

Additional Resources:

LEARN WHAT OUR MANY SATISFIED CUSTOMERS HAVE TO SAY ABOUT Us

"I would like to thank you for the help you have provided us in developing an electroless nickel plating technique on an unusual substrate. The sample platings you provided show that we should be able to reach our goals. I especially appreciate your willingness to take on an unusual job, with the uncertainties that that entails...We are looking forward to working with you in the future on our plating needs."

– Robert K.