Products made from various forms of metal are commonplace in the medical industry. Whether the product is a surgical instrument, orthopedic implant or heart valve, it is imperative it meets extremely high standards in terms of sanitation, reliability and safety. Medical metal finishing plays a critical role in the overall quality and performance of the product to ensure it is clean and free of defects that could endanger patients' health.

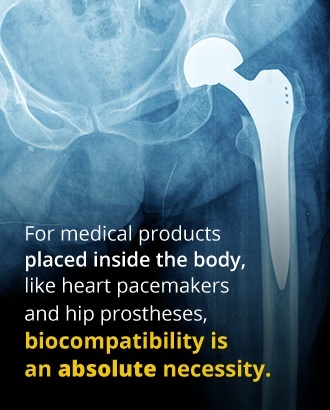

When you consider that many medical products are placed inside the body, such as artificial hips and heart pacemakers, the biocompatibility of the products is also an absolute necessity. Any medical device coating or another finishing process must not pose any harm to human tissue.

Adhering to quality certifications such as ISO: 13485 and ISO: 9001 can ensure the products have smooth, rust-resistant surfaces and will not serve as a breeding ground for bacteria. This can also limit the risk of infections and the possible rejection of an implanted device by the body.

Technological Advancements Poses Unique Medical Metal Finishing Challenges

Many metal products used in the medical industry have traditionally been made from stainless steel or other steel variants. However, advancements in technology have led to the use of other metals. For instance, titanium is now commonly used for hip and knee replacements because of its valuable combination of light weight and superior strength. Screws that are inserted to assist in the healing of broken bones are also made of titanium.

Researchers are also making significant progress in the use of magnesium for manufacturing implants and orthopedic devices. Like titanium, magnesium is a lightweight, strong metal. Magnesium offers the additional advantage of being biodegradable, which eliminates the need for an additional surgical procedure to remove the implanted part after it serves its purpose and is no longer needed. The primary disadvantage of using parts made from magnesium and titanium is that they can be extremely difficult to coat with other metals, which makes the metal finishing process more challenging.

The Benefits of Metal Device Coating

Electroplating is the finishing process that is often used to coat metal products. Electroplating entails placing the part into an electrolyte solution containing dissolved ions of a metal such as gold, silver or nickel. An electric current is then introduced to deposit the ions onto the surface of the part. Plating and coating for medical industry parts is done for many reasons including:

- Cleanliness/sanitation: Cleanliness is critical in any medical product. The product must prevent the development of bacteria and reduce the risk of infection. Many metals exhibit certain antimicrobial properties and provide an excellent defense against harmful bacteria.

- Protection against corrosion and wear: Surgical clamps and other types of medical equipment are reused frequently. The alkaline products and chlorine-diffused wipes that are often used to clean and sterilize medical equipment can promote the onset of corrosion. These metal devices are also subject to normal wear-and-tear over time. Medical device coating can slow the onset of corrosion and wear, which can extend their lifespan and lower the costs associated with frequent equipment replacement.

- Electrical conductivity: Some types of medical devices operate via electricity. Certain metals are effective conductors of electricity, making them an excellent choice as a lining for many forms of medical electrical equipment.

- Thermal conductivity: Certain metals are beneficial in various medical procedures due to their superior thermal conductivity. This gives them the ability to attract heat away from the body and minimize the risk of adhesions or burns.

- Strength: Certain parts and equipment used in the medical field require welding. However, many of these parts are not well-suited to the welding process. Electroplating can strengthen and support the weld area to provide a more reliable adhesion. It is especially effective when welding dissimilar metals such as nickel titanium and stainless steel.

- Providing a radiopaque region: Coating medical devices with a high-density metal such as gold can create a radiopaque area. This blocks radiation administered during procedures such as X-rays, rather than allowing it to pass through, resulting in enhanced X-ray pictures.

- Coating catheter braids: The electroplating process can be used to coat the surface of medical catheter braids, which locks braid intersections together. This helps improve accuracy when inserting the catheter and makes the device more resistant to kinks.

How Does the Patient Benefit From Medical Metal Finishing Processes?

Manufacturers are not the only ones who can experience the advantages of medical device coating — patients can also reap many benefits. The trend in health care is to employ minimally invasive medical procedures whenever possible. Many electroplating techniques are conducive to manufacturing medical equipment and surgical instruments that are compatible with these types of procedures. This can help reduce patient recovery time and keep healthcare costs under control.

What Types of Metals Are Used in Medical Device Coating?

A wide variety of materials can be used in medical metal finishing procedures:

- Gold

While gold is perhaps best known for its attractive appearance and high economic value, it offers many benefits when used for medical device coating. Gold is extremely biocompatible and will not cause adverse reactions when it comes in contact with human tissue or internal organs. Gold also offers superior electrical conductivity, making gold electroplating a valuable process for coating electrical connectors in certain types of medical equipment. Additionally, gold provides excellent protection against corrosion.

Examples of the numerous gold plating applications for the medical field include the manufacturing of gold-plated stents, which cardiologists use to expand restricted arteries during heart procedures. Electronic pacemakers that regulate a patient's heartbeat may also consist of a gold coating. Gold can be used to coat electrical contacts on the lightweight lasers that emergency medical personnel now uses, as well as battlefield surgeons in war zones. The dentistry profession often uses crowns and caps that contain gold.

- Silver

Like gold, silver is classified as a precious metal due to its relative scarcity and high economic value, although it is typically less expensive than gold. Silver is similar to gold in its excellent ability to conduct electricity. Silver is also regarded as the best heat conductor of all metals used in electroplating. Additionally, silver is renowned for its excellent antibacterial properties, making it a preferred choice when plating and coating for medical industry applications. Silver can target and resist components within bacterial organisms.

- Copper

Copper metal is in abundance, making copper plating an extremely cost-effective metal finishing process. Copper is an excellent conductor of electricity and also exhibits the superior thermal properties that are well-suited for medical device manufacturing. A little-known fact about copper is that a copper plate is extremely resistant to bacteria, which is why it is frequently used in the production of laboratory and medical equipment.

- Tin

Like copper, plating with tin offers an affordable metal finishing alternative to precious metals such as gold and silver. Properties that make tin plating attractive to the medical industry include its non-toxicity and excellent resistance against corrosion. Tin is also known for its ductility, which enables it to be deformed without reducing its toughness. A tin coating can be applied as a top coat for lead and tungsten shielding that is used in the interior of magnetic resonance imaging (MRI) machines and radiological equipment.

- Sulfamate Nickel

Nickel is a lustrous, silvery-white metal that offers many beneficial properties, including excellent resistance to corrosion. A bright nickel deposit may be applied for decorative purposes. Nickel without brightening agents can also be used for more functional medical plating applications, which can be achieved by applying sulfamate nickel chemistries to the electrolyte bath. Sulfamate nickel plating features a nickel purity level of 99.9%, while offering superior ductility. In medical plating applications, sulfamate nickel is typically used as an undercoat for gold or silver when coating flexible electrical contacts.

- Plating Onto Titanium

The fact that so many medical devices are now made from titanium has created a demand for a safe, reliable process for plating onto titanium. Nickel and platinum are frequently used to coat titanium to increase its corrosion resistance and harden the surface of the device. However, the process of plating onto titanium is extremely challenging due to the highly reactive nature of this refractory metal. Only a handful of metal finishing companies can implement a technique for plating onto titanium objects that delivers consistent, reliable results.

- Electroless Nickel Plating

Plating can be performed without the use of electricity. A process known as electroless plating provides a metal coating through autocatalytic chemical reaction as opposed to an electric current. Electroless nickel plating can provide a more uniform coating. It can reach areas of the part surface that are unattainable via electroplating. The electroless plating process also offers better control over coating thickness.

Nickel is typically the metal of choice for electroless nickel plating in medical applications. The electroless nickel coating offers excellent as-plated hardness, which can be further enhanced through heat treating. The nickel is co-deposited with phosphorous, offering the benefit of increased lubricity. Altering the level of the phosphorus can make the coating less or more magnetic, depending on the specific plating application. Benefits of electroless nickel plating for medical device coating purposes include increased corrosion protection and greater resistance to most anesthetics.

Request a free quote

For Medical Plating

Specific Electroplating Methods

Depending on the application, electroplating for medical metal finishing can consist of either a rack or barrel plating method. With rack plating, the parts are attached to a rack via metal hooks or bands, and then submersed in the plating solution.

Rack plating is a good choice for plating large, complex or delicate metal parts. However, the process of hanging individual parts can be fairly labor-intensive, which can add to the overall cost of the medical device coating process.

Barrel plating is preferable when coating smaller parts. The parts are placed inside a barrel made of electrically non-conductive material. The barrel is then submerged in a tank containing the electrolyte solution. Flexible metal wires are inserted at either end of the barrel to introduce the electric current. The barrel is slowly tumbled to create the desired coating action.

Other Medical Metal Finishing Processes

There are several additional metal finishing processes used in the medical industry. Passivation of stainless steel is performed to return the metal back to its original state by removing oil and other debris from the surface, then submerging the part in a passivating bath.

The passivation process creates a surface film that results in the reduction of chemical reactivity, which provides benefits such as increased corrosion resistance, a smoother surface and extended product lifespan. Passivation is beneficial in medical applications because it makes it easier to maintain a sterile surface on medical instruments. Passivation is used on titanium and cobalt chrome implants, endoscopic and arthroscopic tools, catheter eyelets and medical device springs.

Electropolishing is another process used by some metal finishing operations. Electropolishing can be viewed as electroplating in reverse. Rather than depositing metal ions onto the surface of the parts, the objects are immersed in an electrolyte solution that removes metal ions. This produces a smooth surface that is desirable for many types of medical devices. Many manufacturers view eletropolishing as superior to passivation due to its heightened microfinishing and corrosion protection capabilities.

Considerations When Choosing a Medical Metal Finishing Process

Many factors can influence the choice of a medical device coating process. Because plating and coating for medical industry applications require a high level of process management, it is important to select a metal finishing company with extensive experience in this area and the resources to manage your project from start to finish. It's also imperative that the selected company and process meet the high quality standards for medical device manufacturing.

You should explore various plating and coating options to identify the most cost-effective solution for your company. In many cases, it is possible to reduce project costs without sacrificing quality by selecting a less expensive plating alternative.

Sharretts Plating Company Can Meet Your Medical Metal Finishing Requirements

SPC can handle medical device coating projects of all types and sizes. Our services include gold, silver, tin and copper electroplating, as well as electroless nickel plating and more.

We're also one of the few metal finishing companies that have mastered the challenging technique of plating onto titanium. With more than 90 years of metal finishing experience, you can also count on us to develop a customized medical metal finishing process that can meet your exact specifications.

SPC is committed to providing the highest possible quality of every medical metal finishing service we provide. We're an ISO-certified company that makes continuous process improvement a focal point in every aspect of our operation. We have the facilities, technical resources and experience to meet the needs of today's manufacturing operations.

Additional Resources:

Get a free quote for our plating and coating in medical industry applications. You can schedule an on-site consultation at your convenience so we can recommend the best medical device coating solution for your needs and budget.

LEARN WHAT OUR MANY SATISFIED CUSTOMERS HAVE TO SAY ABOUT Us

"I would like to thank you for the help you have provided us in developing an electroless nickel plating technique on an unusual substrate. The sample platings you provided show that we should be able to reach our goals. I especially appreciate your willingness to take on an unusual job, with the uncertainties that that entails...We are looking forward to working with you in the future on our plating needs."

– Robert K.